Thank you for visiting the MA Duct Work Inc. Contact Us page. Contact us with any questions or concerns, and we'll respond promptly and fully.

The purpose of Residential Ductwork Design is to properly distribute the airflow, produced by your heating/cooling system, to your house. This involves Return Air (unconditioned) coming into the heating/cooling system. Then, by heating/cooling that air, delivering the newly conditioned air to your home. An improperly designed ductwork systems can cost money through inefficiencies, and in some cases, cause premature failure of heating and cooling equipment. This means that your home's ductwork system is just as important as the equipment used to heat and cool your home.

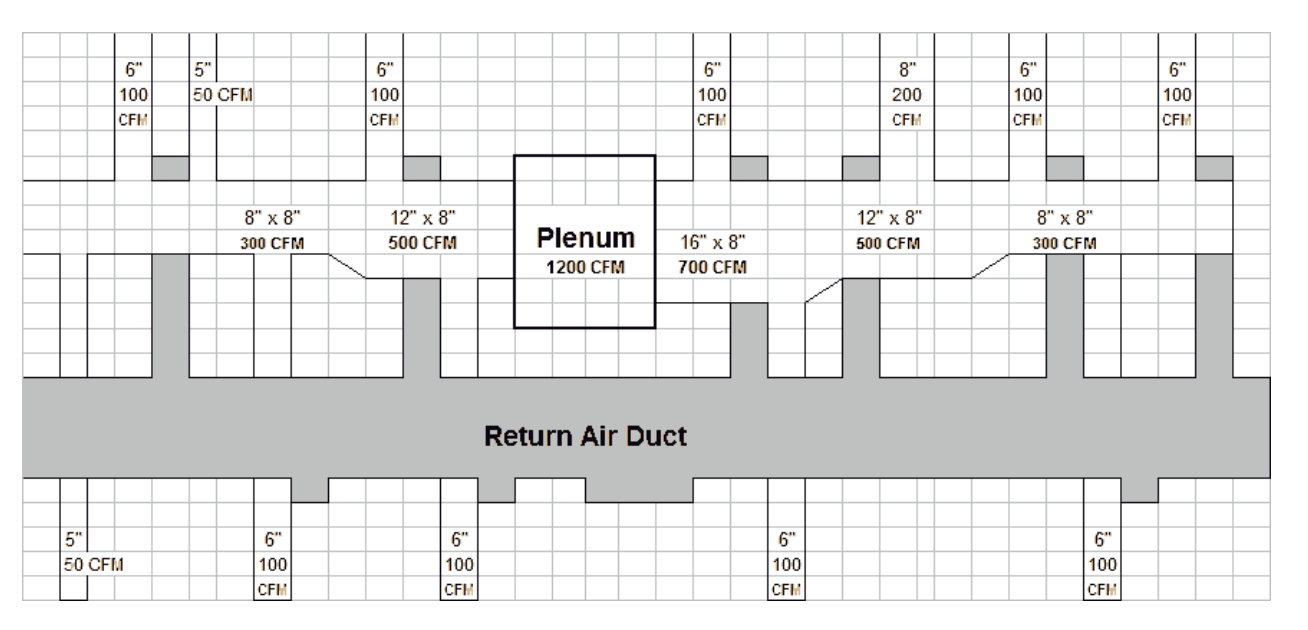

Furnaces and air conditioners require a certain amount of airflow, measured in CFM (Cubic Feet Per Minute), to be passed through the equipment (supply and return ducts) in order for the equipment to function properly and efficiently.

All homes have unique requirements and construction that pose obstacles when designing the ductwork system to accommodate each room with proper airflow. (This is especially true with older homes.)

The Ideal Ductwork System achieves both goals by providing enough airflow to and from the heating/cooling equipment as well as the home. For maximum efficiency, this "ideal" system should also be sealed at all seams with aluminum tape, and should be properly insulated when exposed to unconditioned environments (i.e. crawl spaces and attics).